SuperWeb Digital, a US-based printer solutions manufacturer, today introduced the WEBJet™ Smart Stacker as a finishing offering for its WEBJet™ 200D inkjet press. SuperWeb Digital manufactures customized continuous inkjet presses that can incorporate a customer’s desired finishing capabilities.

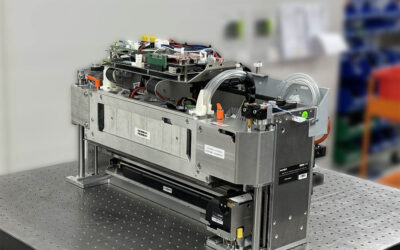

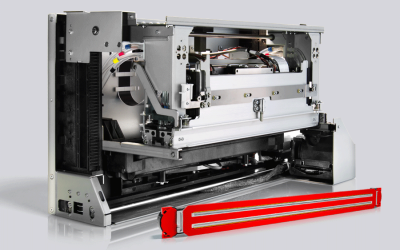

The WEBJet™ Smart Stacker features two separate sheet deliveries in one unit to allow sheet sets to be continuously delivered to the operator without stopping or slowing down the press. In the past, Super Web Digital supplied a conventional, third-party stacker as part of its finishing package. Now, as the printed web is cut on the WEBJet™ 200D inkjet press, the stacker offsets the sheets to create defined sets of statements or book blocks. When the first delivery’s capacity is reached, incoming cut sheets are diverted to the second sheet delivery.

Powered by Memjet, the WEBJet™ 200D is designed to provide Super Web Digital’s Direct Mail, Transaction and Commercial Printing customers with a full range of solutions for handling today’s biggest printing challenges. It enables users to print smaller production runs and variable data, while driving down material costs. The WEBJet™ 200D also prints on a wide range of substrates, and provides an integral duplex function so end users can unwind the paper, print on both sides, and then cut, perforate and stack materials — all on the same machine.

For more information about the WEBJet™ Smart Stacker, please visit: http://www.superwebdigital.com

For more information on Memjet, or to become an OEM partner, please visit: www.memjet.com.