The packaging market is evolving quickly. Whether you are an OEM, a print provider, or a converter, creating success in this changing market requires adaptability. So, when SYSTEC, a Swiss-based leader in flexo printing, wanted to develop new solutions to for the packaging sector, they looked beyond their successful flexo solutions and expanded into digital printing. The result is a new, DuraFlex-powered solution called ARIA. This modular, digital printing machine enables providers to respond to changing customer needs by printing what they want exactly when they want it.

The Changing Packaging Market

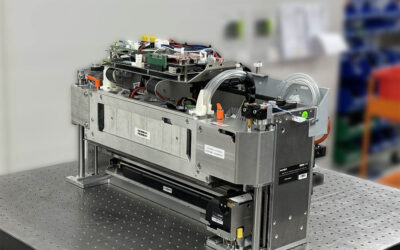

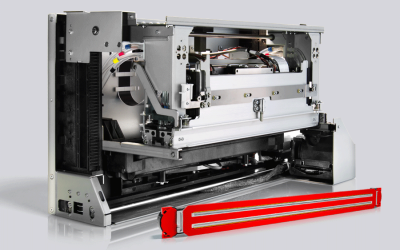

The pandemic quickened the transition to new business models in the packaging market. New distribution and retail sales models changed the management of minimum runs, production batches, and the restocking of packaging in general.nnFlexographic printing, which has always been very competitive compared to other traditional printing technologies, is not suited for these shorter print runs due to setup costs and the need for minimum runs. Digital printing, on the other hand, keeps pace with the market’s demand for customized, short runs that are printed just in time. With a keen understanding of these market dynamics, SYSTEC embarked on a new path towards product diversification. In February 2020, the company began developing a new concept of a digital package printing machine. The development of the machine required a demanding phase of technological integration and close collaboration between the technical teams at SYSTEC and Memjet. The result of this effort is the new Powered by Memjet ARIA, a modular digital printing machine explicitly designed for the personalization of packaging and paper shopping bags. The ARIA is equipped with accessories that make it modular for the customer:

- Automatic loading unit

- On-demand digital priming unit

- Automatic simple uploading of the packaging line.

The flexibility of the ARIA solution allows printers to produce innovative and effective marketing solutions that meet the demands of today’s market. With its ability to print variable subjects, the ARIA lets printers respond to extreme customization needs, such as instant marketing campaigns.

Embracing the Power of DuraFlex Technology

When SYSTEC decided to move to digital, they chose the speed, quality, and modularity of Memjet’s DuraFlex Technology. With a maximum speed of 45 m/ min and a resolution up to 1600 x 1600 dpi, DuraFlex empowers incredible printing performance. The DuraFlex printhead covers a width of 324 mm (when used with a single print head) and operates in 4-color CMYK with water-based inks. This combination of features results in excellent quality at a very low cost per run. SYSTEC values the DuraFlex water-based pigment inks for their high performance, lightfastness, water durable, scratch-resistant, and very low operating cost of a few cents per single copy. Moreover, these inks are safe for food packaging, which expands the possibilities of ARIA to include things like the production of food packaging and bags for fast food companies.

Learn More

To inquire about the ARIA solution and other SYSTEC solutions, visit their website. For more information on how Memjet’s DuraFlex technology supports OEMs in the creation of best-in-breed solutions, contact us.