Guest Author: Dursun Acun of O&PM Europa

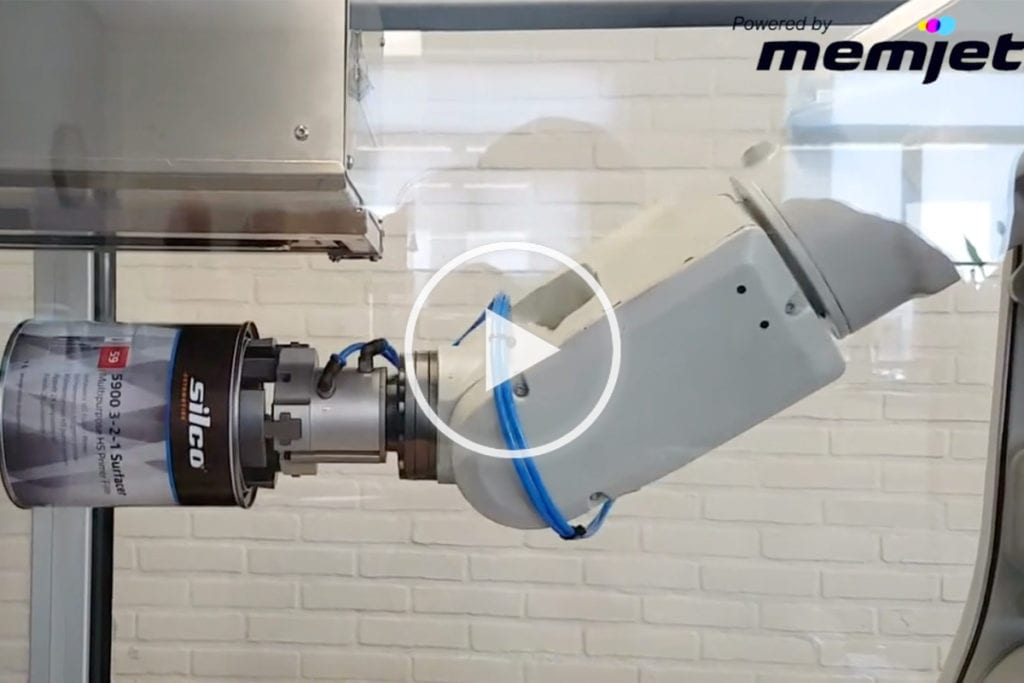

For me, it is very logical to think of eliminating the label as label-less production would not only improve speed and cost, but also have an environmental impact. It would provide a lot more flexibility for the overall supply chain and enable more responsiveness to customers’ demands. We set out to provide a solution to this challenge by integrating our own robotic system with a Powered by Memjet print engine using proprietary coatings to create a self-moving label-less printer called the LabelSaver. It prints high-quality color directly on a variety of objects, including jerry cans, metal paint cans and plastic containers at a rate of 500 jerry cans per hour in full color, 360 degrees.  This is the concept that just a few weeks ago got the LabelSaver product featured as a runner-up in the NL Packaging Awards – an initiative of ManagementMedia, which publishes industry magazines for the Benelux area of Europe. Certified by the World Packaging Organization, this prestigious award and industry recognition rewards innovative thinking and pragmatic problem-solving potential for the labels and packaging of the future. The judges recognized the cost-saving ingenuity of LabelSaver and its direct-to-shape printing by noting, “A concept that allows you to personalize packaging and save labels and as a result, less stock is needed and logistics become more flexible. It is a concept with potential; you could also print other packaging with it.” Their validation and feedback are encouraging as we continue to focus on the development of the technology and equipment to make it commercially viable and available. We want it to be the perfect setup for this market-changing business approach.

This is the concept that just a few weeks ago got the LabelSaver product featured as a runner-up in the NL Packaging Awards – an initiative of ManagementMedia, which publishes industry magazines for the Benelux area of Europe. Certified by the World Packaging Organization, this prestigious award and industry recognition rewards innovative thinking and pragmatic problem-solving potential for the labels and packaging of the future. The judges recognized the cost-saving ingenuity of LabelSaver and its direct-to-shape printing by noting, “A concept that allows you to personalize packaging and save labels and as a result, less stock is needed and logistics become more flexible. It is a concept with potential; you could also print other packaging with it.” Their validation and feedback are encouraging as we continue to focus on the development of the technology and equipment to make it commercially viable and available. We want it to be the perfect setup for this market-changing business approach.

Memjet Powering Future Market Innovation

I wanted to work with Memjet because of the power of the technology, the printhead width and the ability to print four colors at the same time – really for the whole concept of printheads, inks and primers. We believe that Memjet’s printing technology is well suited for the key requirements of the application in terms of optimization and future profitability. For optimal adhesion to any surface, O&PM Europa started developing different primers to complement the printing technology and enhance its application reach. After several years of formulating and testing, we have realized that each substrate (product) demands different characteristics from a primer and that there is no holy grail. We recently used the COVID-19 lockdown period in The Netherlands to further develop our primers and to improve the durability and quality of the solution as a whole. Isolation drives optimization, it seems, because currently we have five primers that have been tried and tested with a high degree of confidence. Memjet has been a very valuable partner – collaborating with and supporting us in development and evangelizing our solution.n

A New Approach for Label Production

We envision a future that gives manufacturers a whole new way to approach the production and application of labels – the savings are just too big to ignore. And, the LabelSaver solution is an example of new innovation using robotics and the right printing technology together to accomplish that goal. We expect that others will follow our lead, but we are confident in our strength and capabilities to lead this market. If you would like to test our market-changing solution, please contact us.