The pandemic caused steep declines in orders across many print sectors. But label production tells a different story: expansion. The majority of products purchased by consumers have some form of a label. Increased demand for consumer products – like that seen in the pandemic – means an increased demand for labels. What is shifting in the label market are the types of labels that are being produced. Label production was one of the first print markets to move to digital printing. The pandemic has sped up that adoption. Research done by NAPCO reveals that most brand owners print labels on digital presses, with more than 80 percent producing prime labels digitally and over 60 percent of non-prime labels printed on digital color presses. When label providers move to digital printing, more and more of them choose inkjet. Inkjet technology enables printers, converters, and brand owners to keep pace with the demands of today’s label market.

Inkjet Printing: Meeting the Demand of Today’s Label Markets

NAPCO Research’s study Lowering Entry Barriers in Digital Printing for Packaging found that over half of printers/converters print labels or tags on inkjet devices. These users choose inkjet because it enables them to keep pace with changing customer demands and opportunities, including personalized, shorter print runs, food safety, and sustainability.

Produce Personalized, Shorter Print Runs

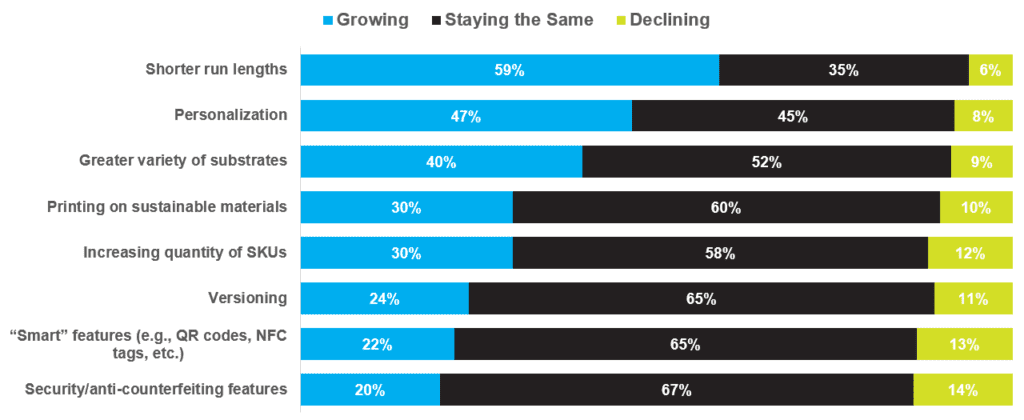

Today’s markets move quickly. Brand owners are looking for ways to respond so they can grow their brands. As a result, providers turn away from printing and storing large volumes of labels and embrace inkjet solutions that can produce shorter-run lengths of personalized labels that better fit the market demands. These shorter run lengths support the trend toward more product varieties (SKUs) and personalization that can grab attention and create engagement with consumers and, in some cases, offer protection against counterfeiting. Moreover, inkjet offers converters and print service providers the opportunity to meet brands’ expectations for high-quality graphics with variable imaging and data while providing a lower cost of ownership than competing digital print technologies.

Gain Access to a Variety of Substrates

Meeting the needs of the market requires greater flexibility when it comes to substrates. Being able to print on a variety of substrates opens up more market opportunities for providers. Because inkjet is a non-impact printing technique, it can accommodate various substrates, including film and paper labels, pre-die cut, and matrix-free rolls with high reliability. Brands also like the offset-like quality that inkjet technology can produce on coated and uncoated substrates—while also creating a label that is resistant to damage from light, moisture, and abrasion.

Simplifying Food Safety

The majority of labels produced today are for food products. Labels produced for this market must meet stringent—and often confusing—U.S. Food and Drug Administration (FDA) regulations that ensure their labels do not harm the food and the people consuming it. According to a NAPCO Research/Memjet survey, 43 percent of package printer/converter respondents that serve the food and beverage market report that complying with packaging safety requirements is a critical to moderate challenge. Many providers solve this food safety challenge by using water-based inkjet solutions like those Powered by Memjet new generation inks which were designed for food packaging. These solutions are safer for food products – and the people using the ink. See the White Paper

Producing Sustainable Labels

The FPA Sustainability Outreach and Consumer Conversations report found 82 percent of consumers care about the sustainability of packaging and 79 percent of consumers prefer products in sustainable packaging over products that are not. Brand owners are taking notice, choosing to work with providers who can sustainably produce their labels and packaging. According to NAPCO Research’s study Adding Value to Digital Printing, sustainable packaging is a top priority for brand owners, with 58 percent citing sustainably as a critical factor when selecting printers and converters. Printing labels on inkjet presses is one way to meet the sustainability challenge. Water-based inks used in many inkjet-powered devices inherently contain less harmful chemicals, creating better work environments and cleaner waste streams. And, can potentially cut environmental costs on permits and disposal fees in half compared to other print technologies.nnPrinting short runs of labels on-demand also eliminates waste created from obsolete labels with out-of-date guidelines, regulations, or branding.n

Experience the New Inkjet

Printing labels on inkjet devices offers print providers, converters, and product owners competitive cost structures, faster printing speeds, enhanced image quality, and the ability to print on a wide variety of substrates. While these solutions vary in size, each inkjet-powered label printer brings benefits that enable print providers, converters, and product owners to keep pace with market trends. Several label presses, in various formats, offer up to 1600 dpi print quality and some with specially formulated aqueous inks designed for food packaging applications. Here are some recently announced solutions:

- Arrow Systems’ ArrowJet Aqua 330R is a high-speed, aqueous pigment inkjet roll-to-roll print solution using Memjet DuraFlex® technology to deliver some of the highest production rates (up to 150 ft/min (45.7 m/min) and lowest print costs in digital narrow web label printing.

- The Afinia Label DLP-2100 Mini Digital Label Press can print and finish in-line at up to 60 feet per minute. The press is capable of laminating, die-cutting, waste removal, slitting, and rewinding to finished rolls that are ready for application.

- AstroNova’s QL-850 is a high-performance, wide-format label printer featuring NaturaTM inks for food packaging and Memjet VersaPass® technology.

- AstroNova’s T2-C is a high-capacity, high-volume tabletop label press capable of delivering precision over long runs on pre-diecut labels, eliminating the need for a secondary finishing process.

- The Coaso iCueLabel 420 is a Memjet DuraFlex-powered roll-to-roll label printer producing high-quality labels — including safe food packaging and high-security labels — in a fast, affordable way.

- The VIPColor VP650 is a desktop color label printer that features Memjet’s enhanced water-resistant ink technology suitable for chilled foods/beverages and most moisture-exposed products.

Learn More

Don’t miss out on the digital label opportunity. Download your copy of the latest NAPCO research report “Enhancing the Digital Label Opportunity – How Digital Inkjet Printing Is Creating New Possibilities.” Download Report