By Kim Beswick, General Manager-Benchtop & Minipress, Memjet

Today, a company’s growth depends on the level of innovation it brings to managing print. Successful printers, for example, must find new opportunities outside their primary offerings. For brands and manufacturers, innovation comes from deciding how and when to make printing part of their own operations.

Possibilities abound in this type of print market: A commercial printer can expand into packaging, a traditional label converter can add digital printed labels to its product offerings, and a manufacturer can make package printing part of its in-line operations.

In dynamic markets like this, OEMs also need to innovate. Not only must they develop printing solutions with the speed and quality users require, they must meet demand by bringing these solutions to market faster and at a more affordable cost.

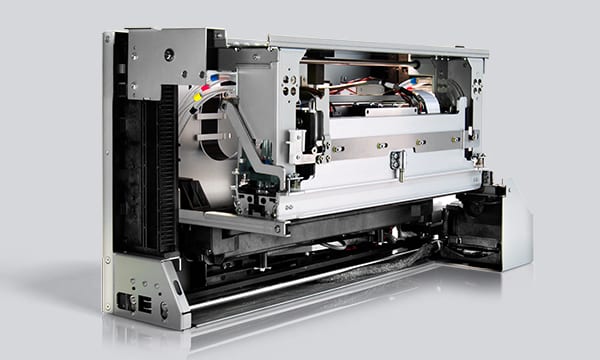

To support this level of innovation, Memjet developed our next-generation printing technology, DuraFlex®.

“Our goal with designing DuraFlex was to create a simple yet robust technology and provide OEM partners with the resources to create affordable printing solutions that are powerful, yet affordable,” said Gianluigi Rankin, director of product marketing at Memjet.

DuraFlex is a modular single-pass print solution that combines Memjet’s signature features of speed, simplicity, and affordability with new attributes such as enhanced durability, A4 and A3+ widths in a four-color printhead, a high-speed data path, and modules that control all printhead functions.

With its compact, modular design, category-leading speed, 1600-dpi quality, and economical cost, DuraFlex provides partners robust resources for creating benchtop and entry-level label and packaging presses as well as light production and wide-format print and packaging applications with quality and speed previously not available in these types of solutions.

The Affordable Move to Inkjet

The flexibility and affordability of DuraFlex provides OEMs and their print customers with a low-risk way to make the move to inkjet or expand their existing product lines with new solutions.

Like other Memjet technologies, DuraFlex is based on a modular architecture that significantly reduces development costs and time, getting OEMs’ products to market faster.

The cost benefits of DuraFlex also extend to the end user. DuraFlex-powered printing solutions are less expensive to buy and operate. DuraFlex’s new long-life, four-color printhead minimizes intervention rates, resulting in higher productivity and profitability for print providers.

Solutions across Market Segments

DuraFlex uses aqueous-pigment inks that are lightfast, water durable, and scratch resistant. DuraFlex inks have been developed for use in indirect food contact applications and are compatible across a broad range of porous, uncoated offset, inkjet-treated, and inkjet-coated media.

This broadly compatible ink set enables OEM partners to use DuraFlex to create a wide variety of solutions across several market segments and applications, including labels, mailing and addressing, robust office and light production printers, packaging, and wide-format graphics.

Together, the features of DuraFlex enable OEMs to create solutions that keep pace with market trends, opening up new business opportunities for manufacturers, brands, and commercial print customers.

“DuraFlex complements other Memjet printing technologies, providing a resource that strategically fits between our VersaPass and DuraLink printing solutions. DuraFlex also adds a pigment ink solution to the compelling dye ink solutions provided by VersaPass technology. With the launch of DuraFlex, Memjet now has the technology to power any type of digital printer in the market,” concluded Gianluigi.