Everything you need to know about food labeling in today’s changing food industry.

INCREASING DEMAND FOR LOCAL, HEALTHY FOOD IS CHANGING THE LABEL GAME

Craft. Fresh. Local. Natural. These aren’t just buzzwords, they’re the result of an awakening collective conscience around food that is driving demand for a broad new spectrum of healthier food products. As consumers seek safer, more environmentally friendly meals—not to mention influence where and how we source our food—the food industry is rapidly changing. And food labeling is changing along with it.

Small and fresh is in. Mass-produced and processed is out. Smaller, focused, nimble food companies are thriving and, to keep their seat at the table, larger manufacturers like Kellogg Co. are adapting by purchasing small manufacturers and adopting their processes to appeal to today’s vigilant, label-obsessed shopper. Consumers are also more immersed in the food and brand experience. Manufacturers small and large are keeping customers engaged by developing brand relationships that are more personal and memorable.

In order to thrive in this environment, the label experience needs to reflect the changes in the food experience.

For example, healthy products naturally call for labels that use clean, safe inks appropriate for indirect food labeling. Small manufacturing will require small batches of short-run labels as well as faster turnaround times that don’t waste label stock when ingredients or messages change. And more personal brand experiences will benefit from labeling that feels more custom and curated. These responses to the changing market all point to one thing: the need for affordable digital solutions that can accommodate short runs, variable data elements like expiration dates and QR codes and quick changes in label requirements whether they come from internal or external sources. Food changes fast but speed and flexibility are what digital technology is all about.

REACTING TO EVER-EVOLVING REGULATORY STANDARDS

As the food industry embraces healthier options, U.S. regulatory agencies are struggling to catch up with food industry innovation and consumer requirements. Despite committing to clarify language like “healthy” and “natural,” the FDA has yet to define these qualities or even propose a draft standard for “Non-GMO.”

Although the EU revised and implemented new food safety and label standards on December 13th, 2016, and introduced a new Novel Food regulation on January 1st, 2018, their food regulations continue to be reviewed and evaluated in light of new novel foods types and new food safety challenges. For example, the EU has current or ongoing evaluations—labeled as routine “Fitness Checks”—on nutrition and health claims, plant protection products, food contact materials, food irradiation and feed additives that will lead to more in-depth assessments of new food labeling principles and requirements in the future.

Based on the evolving nature of food itself, we can anticipate that regulatory standards will continue to expand with regards to food labeling, and therefore, food and beverage companies will continue to need to adapt and change labels quickly. If you want to avoid waste, the old way of pre-printing labels just won’t work in this market.

FOOD LABELING TRENDS TO WATCH

“Food and beverage accounts for 60 to 65% of the entire labels market“

- Clean labels: With food label scrutiny at an all-time high, customers only want to see ingredients they can read and understand. Claims of healthy and nutritious need to be backed up by the ingredients they contain.

- Growing SKUs: SKU counts are going north for many food manufacturers, which means label printers need to be more nimble than ever, adapting to short runs with minimal transition time and minimal set-up cost.

- Storage is out: In a market where product information can change at any moment, pre-printing and storing labels is a thing of the past.

- Home delivery is in: As e-commerce makes food pickup, catering and delivery services more common, consumers are trading shopping carts and their squeaky wheels for the convenience of online ordering and grab-and-go healthy meals. And with it comes an increased need for personalized short-run labels that can be produced on-demand and communicate freshness and expiration dates as well as tell the story behind the company and product.

- Food safe labels: As label converters and food manufacturers endeavor to ensure the safety of UV reactive ink components and processes, demand is growing for water-based low-migration inkjet solutions that minimize the impact on food and human health.

- QR codes and other technology: Smart labels enable brands to share important details about food safety, food sources and freshness as well as connect customers to more of the brand story.

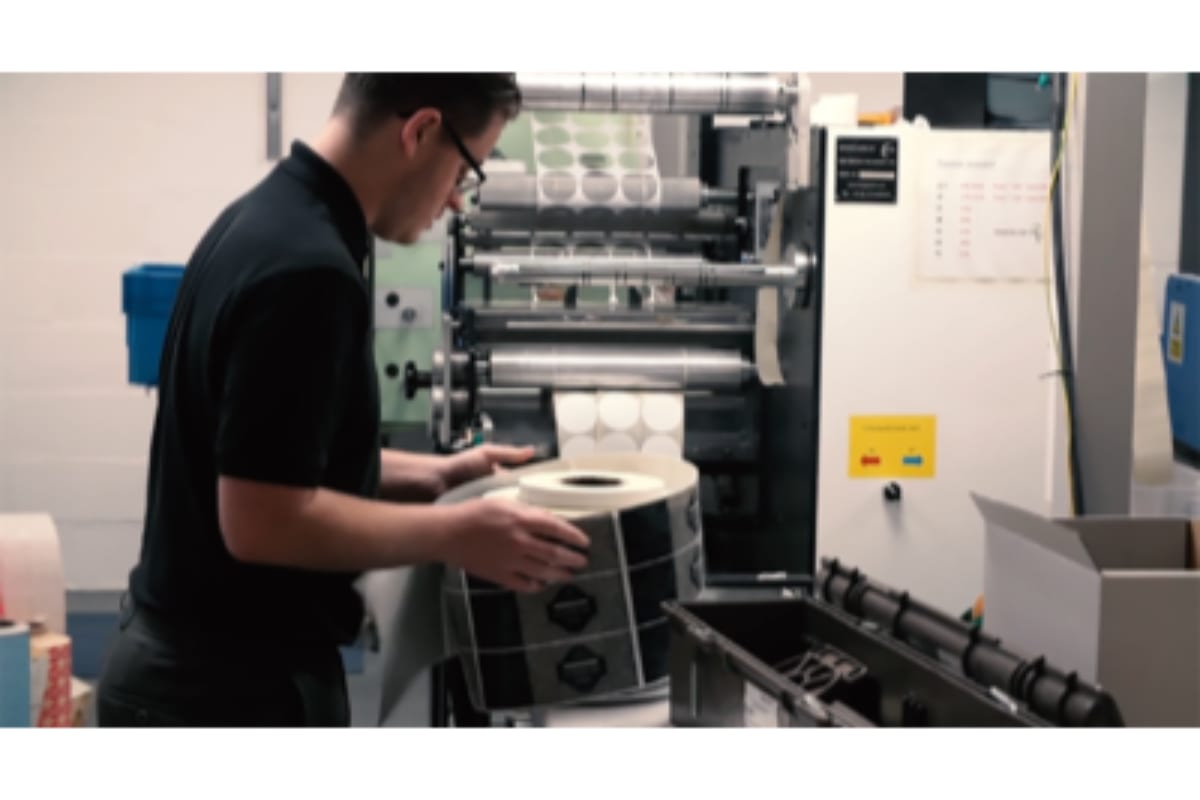

TAKE CONTROL WITH IN-HOUSE LABEL PRINTING

For many food manufacturers, the best way to respond to rapidly changing product information is to take the process in-house where labels can be printed at the speed of production in any quantity desired. And with a range of affordable digital press and tabletop solutions, on-demand label printing is a viable option even for small businesses.

Simple, short-run presses, such as the VIP Color VP750, Afinia L901 and Trojan T2-C, require almost no set-up time and are remarkably easy to use for 1 to 1000 labels at a time. For a more sophisticated press with higher functionality including die-cutting and finishing options, the Afinia DLP2000, New Solution ProEvo, and the Trojan T4 can scale up capacity and offer in-line finishing options such as die-cutting and lamination.

THE LONG AND SHORT OF IT

As the demand for healthier food options continues, the only constant in food labeling is change. In order for food manufacturers to keep up with last-minute product changes, changes to regulatory specifications, growing SKUs and other label customization such as expiration dates, localized marketing messages and brand personalization—they’ve got to rely on a proven digital solution. Food manufacturers will be looking for print partners or in-house solutions that can fulfill their short run variable labeling needs without the setup costs or long timelines associated with offset technology.

Download this white paper to learn how one manufacturer realized a cost savings of 94 percent when they took control of their label production.