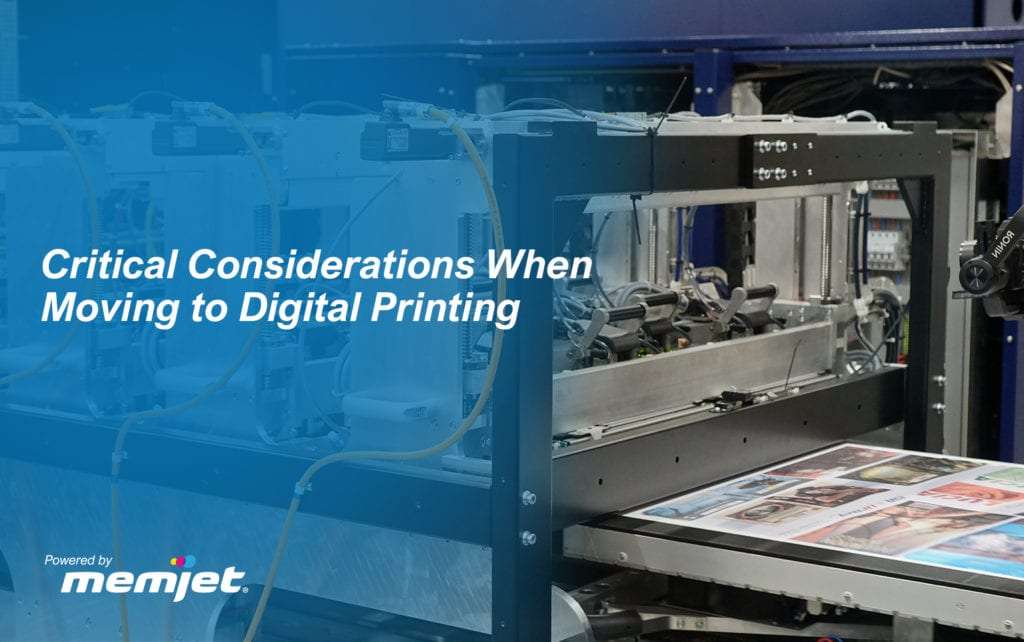

As the entire world wants to print better, faster, and more economically, the printing industry has looked to inkjet as the digital printing technology of choice. That’s because inkjet can print at production speeds (and widths) like offset presses, yet still maintain the precise control needed to deliver the required quality while printing each page uniquely. It has the ability to print directly onto various substrates which makes it an attractive and less complex process compared to alternatives. When thinking about transitioning or adding digital inkjet, here are some critical topics to consider:

1. Technology Investment Costs

Each component of cost can have an impact on the others, so it’s important to look at all of them together as a system – much like how all components of an inkjet press need to work together to produce a quality print. To help printers understand the important question ‘How much does it cost to print?’ we’ve built a model that captures each element, analyses how they interact, and provides a net TCOP, or Total Cost of Print. With inkjet, ink usage is a critical cost driver, and most inkjet printing system manufacturers provide a cost estimator to help printers determine an accurate cost per page to use for estimation purposes. With Memjet-powered systems, the process is relatively simple: we use an estimation tool that accurately (within +- 5%) measures the amount of ink that will be used. We compare that to the amount actually used, as measured on the printing engine itself, to verify. The hardware costs are a matter of simple math – dividing monthly lease payments and service contract costs across the total number of pages to get to a “per page” cost. What isn’t captured here are paper costs (it’s assumed the same paper is being compared, so it’s a constant). The same for labor and electricity costs. Additionally, digital inkjet production – especially when replacing older conventional offset – can eliminate many of the inefficiencies that come with analog offset printing: long ramp-up times, pre-press and plate costs, spoilage and waste, as well as additional labor costs at every step. Not to mention the costs involved with shipping and warehousing longer runs versus printing more “on demand.” To capture the full impact of both the print and non-print costs, most printers will build a full ROI (return-on-investment) model to accurately capture both new and eliminated costs, from electricity to labor, as well as changes in ink costs and labor. In many cases, we’ve seen savvy printers also build new revenue models with capacity and opportunity factors to capture upside potential. In any case, you will see that this is not a “one and done” process as described by Elizabeth Gooding in this article on Inkjet Economics.

2. Sustainability

Just as consumers are paying attention to the impact their choices have on the environment, businesses and brands are putting much more emphasis on the environmental impact they have, too. The expanded role of digital printing translates to a more positive message for sustainability. Printers and end-user customers experience reduced waste from minimizing plate preparation and makeready processes. Further waste reduction comes from reducing print surplus or out-of-date materials, not to mention the time, cost, energy, and distribution savings that come from digitally printing the right materials, at the right time, and in the right locations. In fact, a recent NAPCO Research survey found that combating waste created by rapid product obsolescence was a top challenge for 30% of brand owner respondents. With digital printing, brands, and designers can unleash their creativity to create regionalized campaigns and products, all the way to personalized 1:1 creations. Inks have not traditionally been part of the sustainability conversation, but that is changing. As print providers and food manufacturers strive to ensure the safety of food labels and packaging, demand is growing for water-based, low-migration inkjet solutions that minimize the impact on food and human health. Aqueous-based pigment inks that offer high-quality output, durability on a wide range of substrates, and ingredients approved by regulatory bodies are making inroads into label printing, and are emerging in flexible packaging, folding cartons, and corrugated packaging as well. Memjet offers the safest inks possible: water-based inks. These inks are 100% free of reactive chemistries making them safer to use and better for the environment than alternatives. Read the White Paper

3. Expanding Opportunities

Innovations in technology, inks, and substrates are translating into viable printing solutions that enable more providers to keep pace with market demands and access to new markets. In a recent study conducted by NAPCO Research, survey results showed that printers and package converters gain critical benefits from digital printing:

- Accommodate short-run production needs

- Provide a faster turnaround for their clients

- Add the value of personalization

- Print prototypes or short-run samples in a cost-effective way

- Print only what is needed through versioning.

The survey also cites printing variable images/data, high print quality, faster speeds, and ease of use as the top reasons for adopting inkjet technology.

4. Print Quality

Memjet created something unique in its printing technology; the smallest drop of ink that can be ejected out of a production class print head. With VersaPass®, that’s a 1.1 picoliter drop and with DuraLink® and DuraFlex®, it’s a 2.1 picoliter drop. By using these tiny droplets on a super-fine grid, Memjet systems can print the most precise line art and type – all the way down to .04 point type, which you need a microscope to see. In the same way we image incredibly fine details in a single color, by mixing four or seven colors with that same level of beautiful precision we can create photographic-quality images and printed output that rivals high-end commercial offset at 300 lines per inch. In our website resources, you can find videos showing not only this amazing process taking place, but the stories of people who have implemented complete systems based on our technology.

5. Production Workflow

Inkjet printing solutions like the ones Powered by Memjet are enabling the production of books, collateral, direct mail, and even signage, packaging and labels to be data-driven in a cost-effective way. In order to operate in new segments, your workflow needs to be reviewed and designed to support those new opportunities. Elizabeth Gooding of Inkjet Insights recently discussed designing workflow to drive new opportunities. Learn more about Powered by Memjet digital printing solutions.